BOW Foundry Produces Face Shields for Massachusetts Health Care Workers

When the Weissman Foundry, an open-door design studio for students, faculty, and staff from Babson College, Olin College of Engineering, and Wellesley, first opened its doors 18 months ago, no one involved thought they would be making personal protective equipment for frontline medical staff during a global pandemic.

Located on the Babson campus, the foundry was created to inspire and facilitate collaboration among Babson, Olin, and Wellesley (BOW), one of many initiatives that knit the three schools together.

When the pandemic struck the United States, the foundry community was hard at work establishing what Amy Banzaert, lecturer in engineering and director of engineering studies at Wellesley, referred to as a fourth culture: a BOW experience of inclusivity and engagement that prizes transdisciplinary collaboration and learning.

“Maker spaces have not always been inclusive, so we were excited to ensure that this space was one that truly anyone from any of the campuses felt welcome and safe and comfortable to work in,” she said. “It’s important that everyone feel like it’s a place for them to explore the pedagogical innovations and experiments that we can do in this space, in terms of hands-on learning and teaching, and how we look at transdisciplinary collaboration across the three campuses.”

As the crisis deepened, and it became clear health care workers would benefit from additional protective gear, the foundry stepped in to help.

“Face shields are probably not something we’d be making ever. We’re not really a production facility, even at this small scale,” Banzaert said. “We very much tried to be flexible and to pivot where we needed to be at the given moment.”

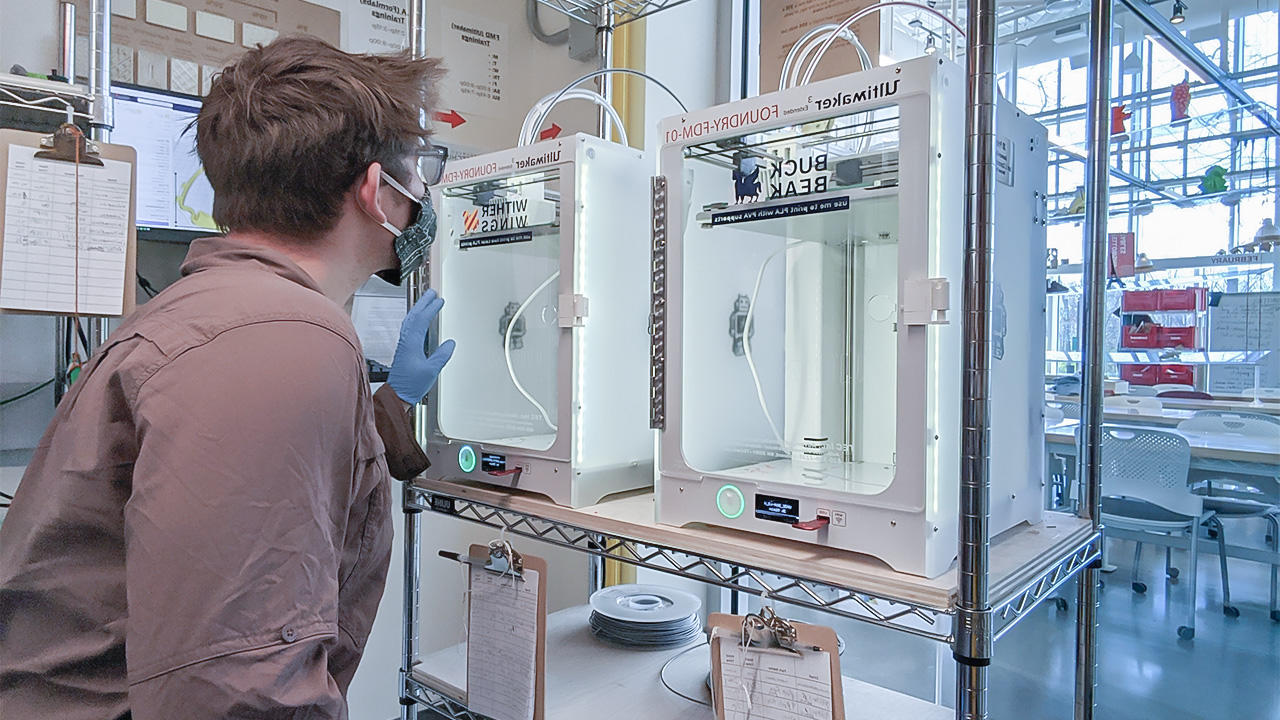

Since mid-March, foundry leaders have been doing just that. Jonathan Griffiths II, the foundry’s assistant director, has spearheaded the production side of the effort to make face shields for Harbor Health, a nonprofit public health agency with six community health centers across Boston, the South Shore, and Cape Cod. As the foundry is following social distancing protocol, Griffiths is currently the only individual at work in its digital design lab, which houses the laser cutters and 3D printers used for producing face shields.

Griffiths said it feels odd to be the only person in a place that is normally bustling with activity, but that he is happy with what they have produced so far. “On a personal level, I feel like I can help by getting out there and making shields,” Griffiths said. “But also, for those that are part of the BOW Foundry community but can’t come in, I feel like they know that they are also helping, by having this community producing and organizing.”

In addition to producing NIH-approved face shields to ship to Harbor Health, the foundry has also created a community collaborative that reaches out to and organizes individual makers and small studios to produce equipment for health care facilities.

“We created a system where people come to us, tell us how many shields they made, and then we coordinate where they can ship them,” Griffiths said. That system includes makers from across the United States. “I’ve been on calls with people from Seattle, D.C., New York City, and Boston,” Griffiths said.

At the end of April, the foundry coordinated its first shipment of shields to the Harbor Health community. “We had an order for our first hundred shields that were shipped out,” Griffiths said. He is expecting that number to increase. “We’re at least going to be able to deliver several hundred shields a week for the next few weeks.”

While the foundry is currently focused on meeting the needs of health care workers on the front lines who are treating patients, both Griffiths and Banzaert are excited about other, student-oriented projects on the horizon. Plans are in the works for a summer pilot program to help students with prototyping, and a push to increase student engagement with the foundry across the three campuses.

“We’re trying to get more and more people to the foundry to see what it’s about,” Griffiths said. “We want students to get in here and see the tools, be able to do the type of things that those of us who are already part of the foundry really love to do, that maybe they haven’t experienced yet because they thought it was too difficult to run a laser printer or 3D printer. Our hope is to help push engagement.”

“Face shields are what made sense in the moment,” said Banzaert. “But long term, it’s really about the student experience, and the faculty experience, and the transdisciplinary collaboration and learning that is possible when the BOW community joins together.”